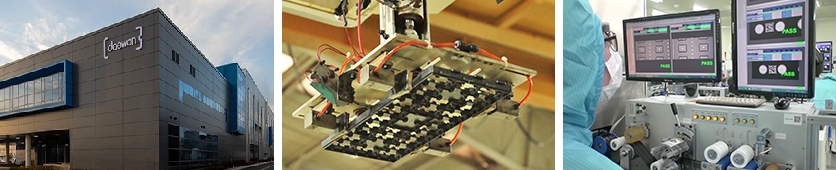

Manufacturing Site

About Daewon

Founded in 1975, Daewon is expanding its business to maintain it position as the leading supplier of semiconductor plastic media carriers. From the beginning, Daewon developed its own nylon price-tag pins for the apparel industry becoming immediately exposed to the demands of selling and exporting material to the United States, Japan, and Europe markets. In the 80s, when the semiconductor industry was rapidly expanding Daewon stepped up designing and shipping IC Shipping TUBE's greatly impacting how IC were handled in circuit production.

In 1991, Deawon advanced again with the development of IC Shipping TRAYs, used exclusively in the United States and Japan, by developing advanced KNOW-HOW while mass-producing the TUBE.

Daewon has established an IN-HOUSE mold team with state-of-the-art mold making facilities and design resources to meet evolving challenges and adapting to the semiconductor market flow. This can only be done with the partnership of excellent human resources trained to keep one step ahead of the market trends.

The company currently has more than 250 clients in 25 countries and is leading the global TRAY market with continuous reinvestment in research and development. They actively participate in the information age modernizing and automating activities utilizing highly tuned ERP SYSTEMs providing the groundwork for the next level of e-commerce coming our way.

Daewon Industrial Co., Ltd. also produces injection molding products such as those wafer related, vacuum molding related, extrusion related, and bare die Carrier Tape related. To manage this wide array of products Daewon has an accomplished supply chain management system tightly controlling raw materials quality and inventory.

About Peak International

In 2008 PEAK International, a NASDAQ listed company was purchased by S+G to produce high-value semiconductor shipping media to become the market leader in the plastics engineering industry that it has become today. It is headquartered in Hong Kong with manufacturing in Shenzhen.

PEAK continues to grow demonstrated by having reliable production capacity, cutting-edge mold design and tooling production capability, a wealth of international market experience, and a highly competitive cost structure. To help maintain this advantage PEAK has become a global leader in plastic recovery and reuse.

PEAK focuses on light weight plastic technology and is actively reducing the use of PVC-based plastics. As a market leader in performance plastic production for the semiconductor shipping materials, including plastic packaging materials, PEAK has pursued technology excellences as well as manufacturing excellence becoming certified as ISO-9002, QS-9000 and most recently with the ISO-14001 demonstrating PEAK’s commitment to strengthening their position in the global market.

About FRC Union

FRC Union in Taoyuan Taiwan was formed in December 2017 by Daewon stakeholders as a HIGH VOLUME specialty plastic molding company to provide best in quality with best on-time delivery to our large regional customers.

Leveraging the long-standing experience and expertise in advanced plastic material fabrication technology accumulated in Daewon and Peak, FRC Union can now offer broad product lines in high volume production leading the industry in uniformity utilizing a new facility designed from the ground up to meet the demands of our growing customer base who have high volume needs with the attention to detail that usually only comes with smaller service providers.

FRC Union is eager to meet customers’ high volume, high quality, and on-time delivery requirements.